The two of the first three high tunnels have been constructed using a wonderful all metal solution manufactured by Zimmerman’s Welding in Missouri.

https://zimmermanshightunnels.com/

This project was partially funded through the NRCS.

https://www.nrcs.usda.gov/programs-initiatives/eqip-environmental-quality-incentives

https://www.nrcs.usda.gov/sites/default/files/2022-10/EQIP-fact-sheet.pdf

Each high-top tunnel is 24’x68′ with 8′ drop-down sidewalls providing 1620 sq. ft. of interior planting space. At times I have called them greenhouses out of my ignorance in farming terms. These facilities are high tunnels dependent on ventilation alone; while greenhouses are supplemented with environmental control systems. Or so I understand.

The project started with prepping the land for the site location:

After meeting with the good folks at the USDA Farm Service Agency (FSA) and Natural Resouces Conservation Service (NRCS), we applied for the Environmental Quality Incentives Program (EQIP) incentives to cost share with the conservation plan which we had in mind. Once the application was filed, we waited for approval before proceeding further. Meanwhile, we took the time to learn how to work this soil, sending samples to the lab, tilling over and over again and even covering with plastic to control loss and erosion.

We began researching manufacturers of the gothic high tunnels we had envisioned for the project. Requesting quotes, evaluating materials, checking references and talking to potential installers took 6 months. So more tilling, leveling and preparing the soil.

Once the project was approved, we placed the order and waited for the delivery. Then we began installation:

With the poles set, next we built the trusses…

The “W” truss and side bracing was an integral part of our decision process to select the Zimmerman product. The “W” truss will allow us to tie-up plants for vertical growth support throughout the tunnel.

Next we assembled the end walls

Then we assembled the drop-down side curtains and pulled the top plastic to enclose the roof.

Getting closer to being finished, we covered the end walls with plastic and polycarbonate

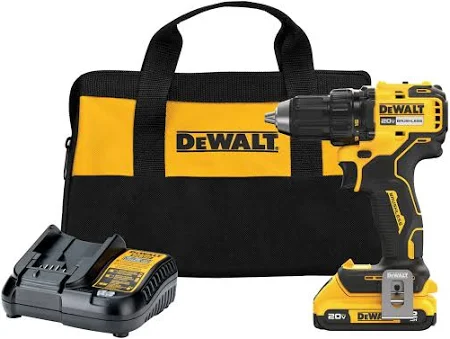

After 500+ hours, the tunnels were complete. Not one of the people who participated in this assembly had ever constructed a tunnel like this. Over 3+ weeks of cooperation, working through material shortages, using new and old tools, many laughs and a very few minor cuts and scrapes, it was time for NRCS inspection. After 7000+ metal screws and bolts, the crew threatened a walkout if I said “guys, this needs to be attached with screws” again. And, I must compliment DeWalt Tools. A brand new cordless drill failed during construction. I called DeWalt, gave the representative the serial number and without any delay, a brand new replacement was sent to the farm – obviously, we all were impressed and satisfied.

On May 20, 2024, we met with the good folks from NRCS and after walking through the installation instructions paragraph by paragraph, the project was deemed complete and satisfactory to the EQIP criteria and rules.

Many thanks to Jose, Ronnie, Reggie, Chuck and Marie for helping bring these high tunnels to the farm. And special thanks to Timothy at Zimmerman’s for expediting the material shortages along the way.

Next, a 3rd high tunnel is planned for the fall of 2024. Stay tuned and volunteers are welcome to come and help build another high tunnel.